Valves play a crucial role in various industrial and residential systems, controlling the flow and pressure of liquids and gases. Their applications span from plumbing to complex manufacturing processes. This article delves into the different types of valves, their functions, and their importance in maintaining efficient system operations. Additionally, we’ll explore the connection between valves and geomembranes, highlighting how these components work together in specific applications.

What are the different types of valves?

Valves come in various types, each designed for specific functions:

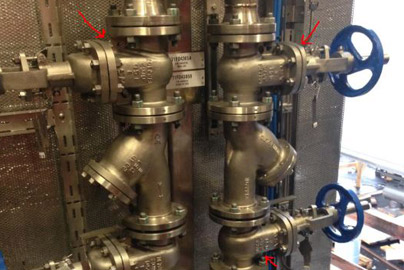

- Gate Valves: Used to start or stop the flow of liquid. They are fully open or closed, with minimal pressure drop.

- Ball Valves: Feature a spherical disc that controls flow. Known for their durability and quick operation.

- Butterfly Valves: Use a rotating disc to regulate flow. Ideal for large volume applications due to their space-saving design.

- Check Valves: Allow flow in one direction only, preventing backflow.

Each type has unique applications and benefits, making them suitable for different industrial and residential needs.

How do valves function in industrial applications?

In industrial settings, valves control the flow of liquids and gases, maintain pressure levels, and ensure safety. For example:

- Flow Regulation: Valves manage the rate of flow in pipelines, ensuring that processes operate within desired parameters.

- Pressure Control: Valves adjust pressure levels to prevent system overloads or equipment damage.

- Safety Mechanisms: In critical systems, valves act as safety devices to prevent accidents or system failures.

By managing these factors, valves help maintain efficiency and safety in industrial processes.

What is the importance of valves in plumbing systems?

In plumbing systems, valves are essential for:

- Flow Control: They regulate water flow to various fixtures, ensuring consistent and adequate supply.

- Shut-off Capabilities: Valves allow for the isolation of sections of the plumbing system for maintenance or repairs.

- Pressure Regulation: They help manage water pressure, preventing damage to pipes and fixtures.

Proper valve installation and maintenance are crucial for reliable plumbing operations and avoiding leaks or blockages.

How do valves interact with geomembranes in environmental applications?

In environmental applications, such as landfill liners or wastewater treatment facilities, valves work in conjunction with geomembranes. Geomembranes are synthetic barriers used to control fluid migration and protect the environment. Valves:

- Control Fluid Flow: Manage the flow of fluids through systems lined with geomembranes, ensuring effective containment and treatment.

- Monitor Pressure: Help maintain pressure levels within systems, preventing damage to geomembranes and ensuring their integrity.

- Facilitate Maintenance: Allow for the isolation of sections for inspection or repair, without compromising the geomembrane’s function.

This collaboration ensures that environmental systems operate efficiently and safely, protecting both infrastructure and the surrounding environment.

Valves are integral components in a wide range of systems, from household plumbing to complex industrial processes. Their ability to control flow, regulate pressure, and provide safety measures makes them indispensable. In environmental applications, valves work alongside geomembranes to ensure effective fluid management and system integrity. Understanding the various types of valves and their functions helps in selecting the right valve for specific needs, ultimately contributing to the efficiency and safety of any system.