trim 12 material

axial flow check valves

5.7 hemi idle air control valve location

cameron t 31

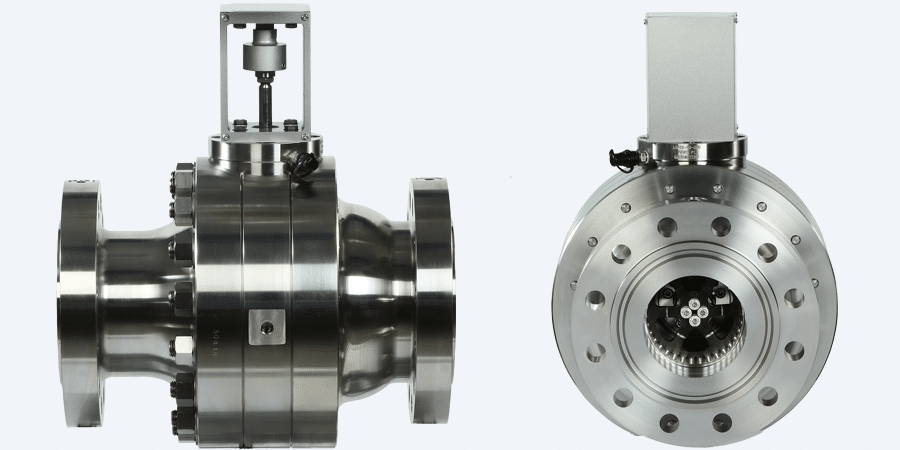

In the rapidly evolving industrial landscape, the demand for efficient and reliable axial flow control valves has surged, underscoring the critical role these components play in operational integrity and system performance. For entities involved in engineering procurement and construction (EPC), along with valve wholesalers, importers, trading companies, engineering companies, brands, distributors, and agents, identifying the top manufacturers of these valves is pivotal. This article delves into the top 10 axial flow control valve manufacturers worldwide in 2024, offering insights into their offerings and how they cater to the sophisticated needs of the industry.

Top 10 Axial Flow Control Valves Manufacturers

TOP 1. Samson Ringo

Ringo is part of the SAMSON group, which has a broad portfolio including various types of valves such as globe valves, angle valves, gate valves, check valves, and more, designed for a wide range of applications across several industries.

The Samson Ringo Axial Flow Valve stands out for its superior Cv value and rangeability, ensuring efficient fluid control. It features a cage-guided balanced plug for smooth operation and a variety of cage designs suitable for critical gas and liquid applications. Its unique Rotary-to-Linear drive mechanism simplifies actuator requirements, allowing for the use of standard electric or pneumatic actuators. This valve offers precise control with reduced friction and is environmentally friendly with low emissions. Its innovative design minimizes force requirements and offers unmatched capacity for its size.

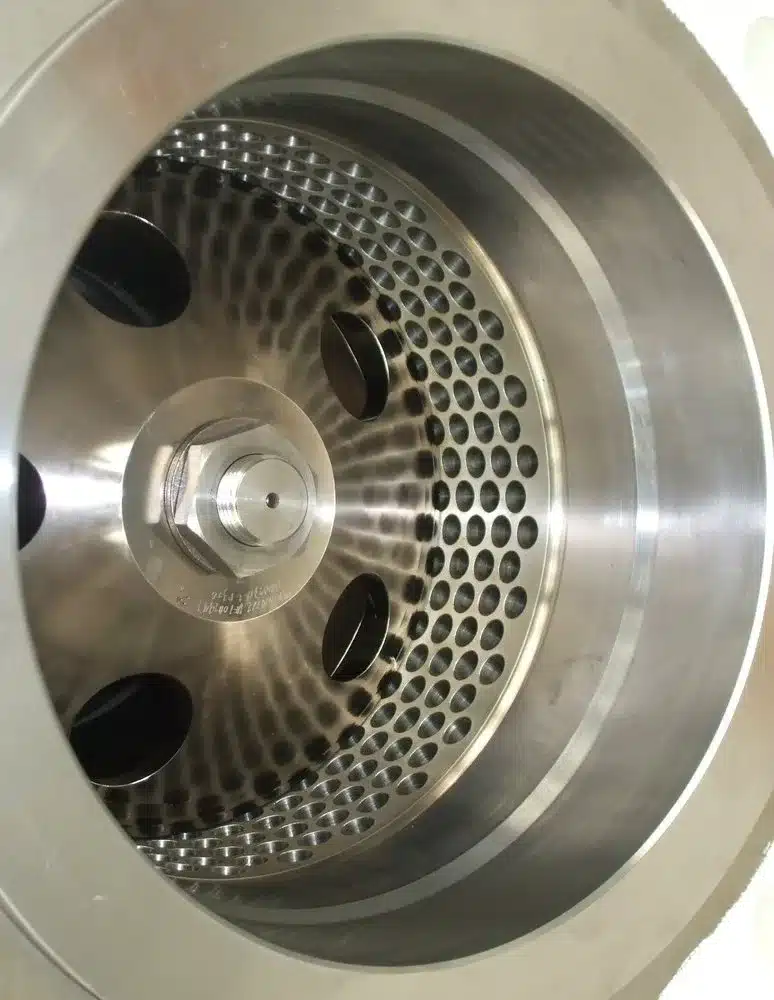

STD Cage

This multi-hole cage is designed for non-critical services that require regulation.

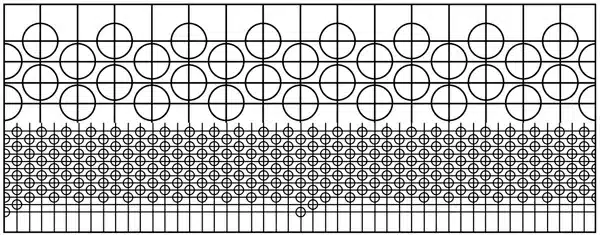

DobDrill

A combination of LDB at lower strokes and STD at higher strokes increases valve rangeability.

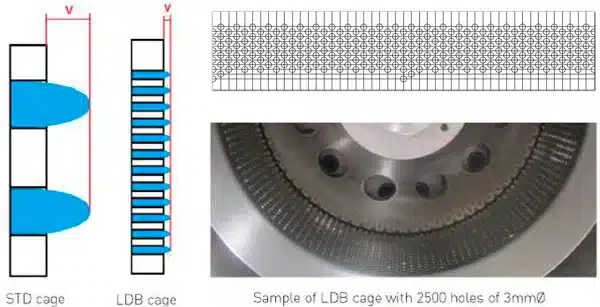

LDB (LOW db)

This is a multi-hole cage with a pattern of small holes aimed at reducing noise levels by decreasing jet diameter and increasing fp.

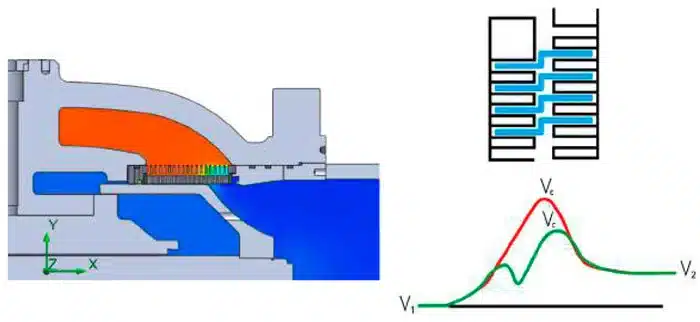

DobCage

This design merges two LDB cages with a small expansion area between them, offering maximum noise protection through a multi-stage effect. For special services facing high critical noise levels, more than 2 stages (up to 4) can also be provided upon request.

Address

Polígono Industrial Empresarium,

Calle Romero, 6

50720 Zaragoza Spain

Phone

+34 976 45 49 40

[email protected], [email protected]

TOP 2. Mokveld Valves

Mokveld, a leading expert in the field, provides the gas, oil, and water industry with state-of-the-art valve systems engineered for essential control and safety applications, leveraging deep industry knowledge and technological prowess to meet the demanding needs of its clients.

Mokveld Valves’ axial flow control valves excel in streamlining flow to reduce turbulence, erosion, and vibration, cutting process downtime and maintenance costs. The Total Velocity Management® concept ensures intelligent fluid velocity management throughout the valve. Their high capacity allows for smaller valve sizes without sacrificing performance, offering precise control even at minimal openings and enabling high turndown rates for versatile application. Additionally, their compact design significantly reduces weight, further enhanced by the option for spring-opposed actuators, making them an efficient and silent solution for various control needs.

Address

Nijverheidsstraat 67

2802 AJ Gouda

The Netherlands

Phone

+31 182 59 75 00

[email protected]

TOP 3. Emerson, Fisher

Emerson’s Fisher valves are synonymous with quality and versatility. Their wide range of axial flow control valves is designed to meet the diverse needs of the industry, from simple flow control to complex automation systems.

The Type FLV axial control valve, adhering to the IEC60534 standard, is tailored for pressure or flow control in natural gas systems. Suited for non-corrosive gases, it features an optional silencer cage for high differential pressure settings to mitigate noise, and recommends an upstream filter to prevent clogging.

Principle of Operation

The Type FLV axial control valve adjusts the gas flow based on the desired system pressure and/or flow rate. Any changes in pressure and/or flow rate are detected by sensors and relayed to a controller (PLC). The controller then sends a signal to the electric actuator, which turns and shifts the control valve shaft and plug assembly to regulate the gas flow. When downstream demand rises, the downstream pressure momentarily drops. The controller responds by signaling the electric actuator to turn counterclockwise, opening the valve further to increase gas flow and stabilize downstream pressure. On the other hand, when downstream demand falls, the downstream pressure momentarily goes up. The controller directs the electric actuator to turn clockwise, closing the valve to decrease gas flow and keep downstream pressure steady.

Valve Installation

The Type FLV axial control valve needs to be installed in horizontal pipes, ensuring the actuator is positioned above it. Additionally, it’s important to follow the direction indicated by the flow arrow mark on the valve’s body. For safety reasons, a block valve must be installed both immediately upstream and downstream of the control valve when it’s shut down.

Address

Sede Amministrativa/Administrative Headquarters: OMT Tartarini, Via Clodoveo Bonazzi 43,

40013 Castel Maggiore (Bologna), Italy

Phone

Americas

McKinney, Texas 75070 USA

T +1 800 558 5853, +1 972 548 3574

Europe

Bologna 40013, Italy

T +39 051 419 0611

Asia Pacific

Singapore 128461, Singapore

T +65 6777 8211

Middle East and Africa

Dubai, United Arab Emirates

T +971 4 811 8100

[email protected]

TOP 4. FG Valvole

FG Valvole specializes in axial flow control valves, offering solutions for both tight isolation and throttling services. Their valves, designed for rapid closure, are ideal for applications requiring quick response, such as SDV-HIPPS. These valves are engineered for extended life and minimal maintenance, featuring a balanced-pressure disc design. With a vast material selection including carbon steel, stainless steels, and titanium, FG Valvole meets to a range of applications from production to tank loading. Their design options include plug type, single cage, and multi cage trims to manage large flow rates and high pressure drops efficiently.

Address

Via XXV Aprile 1945, n. 27/29/31 – 24050

Zanica (BG) – Italy

Phone

+390354541160

[email protected]

TOP 5. Advanced Technology Valve S.p.A.

Advanced Technology Valve S.p.A. (ATV) specializes in axial flow control valves, offering a comprehensive range of products for various applications. These valves are designed to provide precise control over a wide range of process conditions with a single valve, featuring high Cv and smooth throttling action. ATV ensures reliability and high performance in critical applications. Their product line includes axial flow on/off and control valves, rising stem ball valves, swing check valves, and more. ATV’s axial flow valves contribute to efficient fluid control in industries such as hydrocarbons processing and pipeline applications.

Address

Via Ombriano 2

I-23823 Colico (LC), Italy

Phone

+39 0341 932111

[email protected]

TOP 6. PETROLVALVES S.P.A

PETROLVALVES S.P.A manufactures axial flow control valves primarily for the oil, gas, and power generation industries. These valves are designed to regulate the flow of fluids in pipelines, offering efficient control over fluid movement. Here’s a brief overview:

Purpose

Axial flow control valves are used to regulate fluid flow in pipelines, allowing precise control over the rate and volume of fluid passing through.

Applications

They find applications in various industries such as oil, gas, and power generation where accurate fluid flow control is critical.

Features

These valves are engineered to withstand high pressures and temperatures commonly encountered in industrial processes. They offer reliable performance and are often designed for specific operational requirements.

Address

Viale Luigi Majno 17/A, 20122 Milan, Italy

TOP 7. Goodwin International

Goodwin International specializes in axial flow control valves, designed for demanding applications requiring tight shut off, reliability, and precise control. These valves offer fast opening/closing, crucial for various industrial processes. Key features include a novel split body design, which enhances functionality and acceptance.

Goodwin’s axial flow valves ensure tight shut off, high reliability, and precise control for demanding applications.

The valves feature a split body design, enhancing functionality and acceptance across industries.

Goodwin’s range includes axial isolation and control valves, designed for both isolation and control duties in various industries. These valves reduce turbulence through the valve body, ensuring efficient axial flow.

Address

Plantation Rd,

Newstead Industrial Estate,

Stoke-on-Trent, ST4 8HU,

United Kingdom.

Phone

+44 (0) 1782 220000

[email protected]

TOP 8. ARI Armaturen Group, Comeval Valve

ARI Armaturen Group is a global provider of valves for control, isolation, safety, and steam trapping in industrial processes and chemicals. COMEVAL Valve Systems, established in 1975 and acquired by ARI Armaturen Group in 2010, specializes in designing high-quality valves. Combining ARI’s expertise in valve manufacturing with Comeval’s specialization in flow control, the collaboration likely produces high-quality axial flow control valves meeting diverse industrial needs.

Address

Les Rotes, 15

46540 El Puig (Valencia) España

Phone

(+34) 961 479 011

[email protected]

TOP 9. VRG Controls LLC

VRG Controls is known for its precision-engineered control valves that optimize flow and pressure control, ensuring operational efficiency and system stability. The VRG Controls LLC axial flow control valve is a high-performance valve designed for natural gas regulation. Here’s a concise overview:

Purpose

It’s engineered for controlling natural gas flow in pipelines.

Features

The VRG axial flow control valve likely incorporates advanced features for efficient regulation, such as high flow range-ability and a full opening design.

Applications

Primarily used in natural gas transmission pipelines.

Address

1199 Flex Ct Unit B,

Lake Zurich, IL 60047

Phone

(844) 356-9874

[email protected]

TOP 10. KURVALF VANA A.Ş.

The KURVALF Axial Flow Control Valve is a high-performance control valve designed for applications requiring precise flow rate and pressure control. Here’s what you need to know:

Functionality

Axial control valves regulate flow in the same direction as the line flow, offering efficient control over flow rate and pressure.

Design

They feature a linear motion closure member, enabling precise control with high flow capacity.

Advantage

- Compact design with high flow capacity, suitable for ON/OFF and control applications.

- Streamlined flow path minimizes turbulence, erosion, and vibration, reducing downtime and maintenance.

Performance

The AFCV80 series offers low flow resistance coefficient, ensuring efficient operation.

Address

Çalı Mah. Çınarlık Cad. No: 8, 16275 BURSA / TÜRKİYE

Phone

+90 224 482 46 97

[email protected]

Capacity Sizing Procedures For Axial Control Valves

To estimate the flow capacity and determine the valve diameter, follow 2 steps.

Step 1: Sizing Flow Rate Q

Calculate the required Cg with the following formula:

For gases with varying densities, you need to adjust the flow rate calculated using the above formulas by multiplying it with the correction factor.

Step 2: Calculate DN

Calculate the needed Cg using the following formula:

The formulas mentioned are specifically for calculating the flow rate of natural gas. Should you need to calculate the flow rate for other gases, simply divide the value (Q) by the correction factor (F).

Gas Conversion

| Gas | Relative Density(d) | Factor(F) |

| Air | 1 | 0.78 |

| Butane | 2.01 | 0.55 |

| Propane | 1.53 | 0.63 |

| Nitrogen | 0.97 | 0.79 |

After determining the DN (Diameter Nominal) of the valve, ensure the gas velocity at the outlet flange doesn’t surpass 150 meters per second. Use the formula provided below:

Symbols

Q = Natural gas flow rate in (Stm 3 /h)

P1 = Absolute inlet pressure in bar

P2 = Absolute outlet pressure in bar

Cg = Flow coefficient

C1 = Body shape factor

d = Relative density of the gas

V = Velocity (m/s)

Q = Natural gas flow rate in (Stm 3 /h)

DN = Valve nominal diameter (mm)

Pu = Inlet pressure in relative value (bar)

Conclusion

The above Top 10 axial flow control valve manufacturers are available for your choose. THINKTANK is currently developing this axial flow valve, which will be put into formal production in the second half of 2024. We sincerely welcome brand owners, engineering companies, EPCs, and valve distributors contact us and we can provide OEM services for free. [email protected]