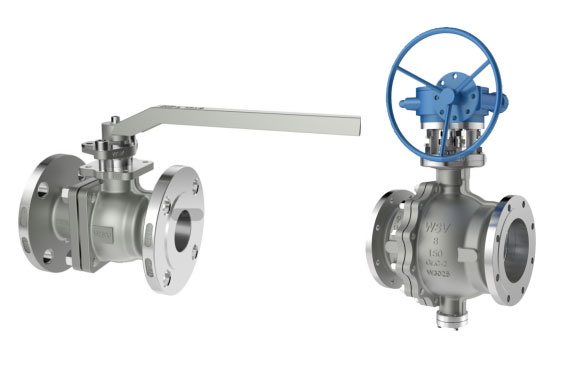

1. Appearance

The appearance is different. Trunnion ball valve body with a fixed shaft on the bottom. And if the ball valve body has a device for injecting grease, it is basically a trunnion.However, can we say it must be a floating ball valve if it is without injecting device? Of course not, small size (such as 2", 150LB) trunnion ball valves are usually not filled with injecting device either.

2. Sealing face

As the ball is floating, under the pressure of the medium, the floating ball will move and against the downstream sealing face, so the seal of the floating ball valve belongs to the one-way seal. The sealing of the floating ball valve is realized by the pressure of the medium. The floating ball will be pressed against the sealing face under the action of pressrue to realize sealing, when it is closed.

The ball of the trunnion ball valve cannot be moved, so the both sides of the trunnion ball valve must be sealed. The ball don’t produce displacement when the trunnion ball valve is closed. It depend on the moving of floating seats, and press against the ball under the action of the media pressure to realize sealing.

Since the sealing principle is different, the requirements of the two ball valve are different on the sealing face material, especially the floating ball valve must be able to bear the pressure caused by the floating ball.

3. Characteristics

Usually, China Monel Ball Valve Supplier the service life of trunnion ball valve is longer than floating ball valve. And it can release pressure automatically without a relief, when the medium temperature in the valve rises and causes abnormal pressure rise. This is very important to ensure the safety of industrial production.

Floating ball valve has smaller size and easier to operate.

4. Application

The floating ball valve is suitable for medium and low pressure and usually has a small diameter.And the working temperature usually from -29℃ to 425℃.

The trunnion ball valve can be used in high pressure conditions and the size can be up to 60 inches.It is a kind of double-block-and-bleed (DBB) valve. It can block both upstream and downstream media. And when the pressure in the middle cavity is greater than the seat spring force, the seat will be pushed open to release the pressure inside the chamber to ensure safety.